rjw

Chief Bottle Washer

People Skills : 7770

Registration date : 2009-03-31

Location : Miami

|  Subject: Re: CNC is Finally up and Running ! Subject: Re: CNC is Finally up and Running !  Thu Jan 20, 2011 10:28 am Thu Jan 20, 2011 10:28 am | |

| - rdubard wrote:

- rjw--where do you get your table feeds from? Maybe I'm used to a high horsepower machine, HSS bits, mist coolant only, and large endmills, but by my calculations I would NEVER get more than 15ipm on the table.

Maybe it has something to do with your speeds? I run Al at 300fpm at the tooth. For a 1/4 inch diameter endmill, that gets me a spindle speed of 4600rpm. (my mill maxes out at 3500, and I like to keep it at 2500 max, but let's ignore that). If the mill is a 2 flute, and each tooth cuts 2 thousandths a pass, then I'm feeding 4 thousandsths per revolution (times 4600 revolutions per minute) gives me 18 ipm on the table. Let me restate that--spindle at 4600rpm, table at 18ipm.

You said to cut at eighteen thousand rpm (4x what I would ever do), which in my opinion, will undoubtedly make a dry bit hot enough to weld, and on top of that the incredible table speed of two hundred inches per minute (11x what I would do) would do one darn heavy chip thickness.

But hey, YOU are the machinist, so what the hell am I talking about? Am I missing some giant piece of information? Is the difference entirely accountable from using carbide and flood cooling? I designed a machine to specifically be use to cut robot parts. I always uses carbide tooling, but ideally, I use TICN coated carbides, from Niagara....ex: micrograin carbide, TICN coated 1/4" 3 flute with 3/4" depth of cut. In that I use a router motor, this puts me into the realm of high frequency (or highspeed) machining. Do a search on that and you might be surprised at how fast the spindle speeds and feedrates are....while depth of cut is normally very small. Your machine, being a maunal mill with cnc retrofit, falls into a different category, and therefore, with the much slower spindle speeds, you can use cheaper tooling and need to run a much slower feedrate, expecially without flood cooling. Not saying that 1 is better than the other, just different setups , but almost any setup can be optimized. Frisco's machine with the single speed high rpm motor and no cooling at all, makes it a tough job to tweak. | |

|

rjw

Chief Bottle Washer

People Skills : 7770

Registration date : 2009-03-31

Location : Miami

|  Subject: Re: CNC is Finally up and Running ! Subject: Re: CNC is Finally up and Running !  Thu Jan 20, 2011 10:37 am Thu Jan 20, 2011 10:37 am | |

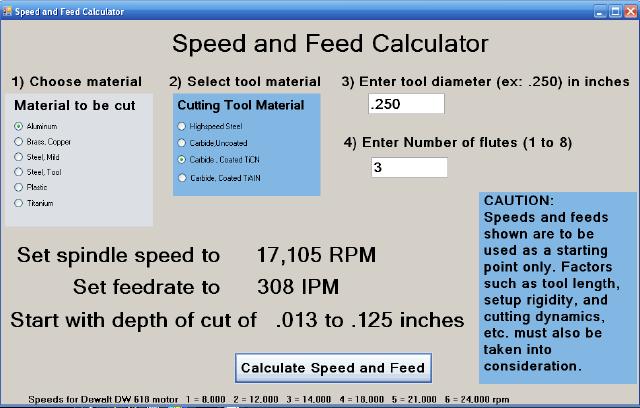

| I also wrote a small program that I reference in order to quickly determine speeds and feeds Here is a sample screenshot  I chose a Dewalt router for this machine because.. 1) it is relatively inexpensive 2) Speeds go as low as 8k rpm 3) collet system is like a true machine tool spindle 4) rigidity isn't bad....I've cut s7 drums with this 5) it is a constant torque motor, meaning that it tries to hold the set rpm wile tool is engaged in material..much better than a porter cable router (imo) My machine is the prototype and also has a 6 station turret style automatic toolchanger...i.e. there are 6 actual router motors mounted on a turret. MLEC has a single tool version, but in a very nice enclosure that I also designed. sorry for the thread hijack | |

|